FREE UK DELIVERY

On orders over £60 (Trade £95)

FREE UK DELIVERY

On orders over £60 (Trade £95)

Technical Knowledge

Experienced & Dedicated Staff

Trade Discounts

Register or login for trade prices

09 October 2020

Glazing is a major part of a finished window for weatherproofing, security and aesthetics. Below we raise the key problems and provide advice on how to overcome these to produce a finished window that not only lasts longer, but is more efficient to produce and complies with FENSA regulations.

There are several problems that can cause unintended customer call outs. One of these are Georgian bars that de-bond, the problem here is not the tape but the glass. Usually cleaned down with glass cleaner and then bonded to the window using some form of tape.

The problem is the glass cleaner and that it has surfactants. These are the agents that cling to the water and grease (Dirt) to enable it to be “cleaned”. These surfactants leave an invisible film that can hinder the adherence of tapes and in time the Georgian bars will begin to delaminate from the glass or fall off. To overcome this problem, we highly recommend that all areas where bars and beads are fitted, cleaning the glass surface with IPA. IPA is over 99% alcohol and will take the glass to its original condition. Also using one of the popular Qwood bar profiles will help, as they do not shrink and expand like traditional bars, therefore putting less stress on the tapes.

The other common problem area with finished window beading is on the bottom bead. Exposed the most to weathering and moisture is the pinning. It becomes exposed by the filler covering the pins breaking down leaving unsightly dimple marks on the glazing bead. Some companies secret nail, with a rebate taken out of the bead and a nail fired through the bead and into the sash, then the rebate filled with silicone, tape or rubber. We consider the best option is to use one of the three non pinned glazing beads SD1, SD2 or GBC1, not only does this avoid pinning it will also not shrink or warp like timber beads. This will produce a better finished window that will last longer and be more efficient to produce. Depending on where the glazing of the window is to take place can determine which technique is used.

The correct applications for factory and site glazing and where our range of products should be applied, can be seen below

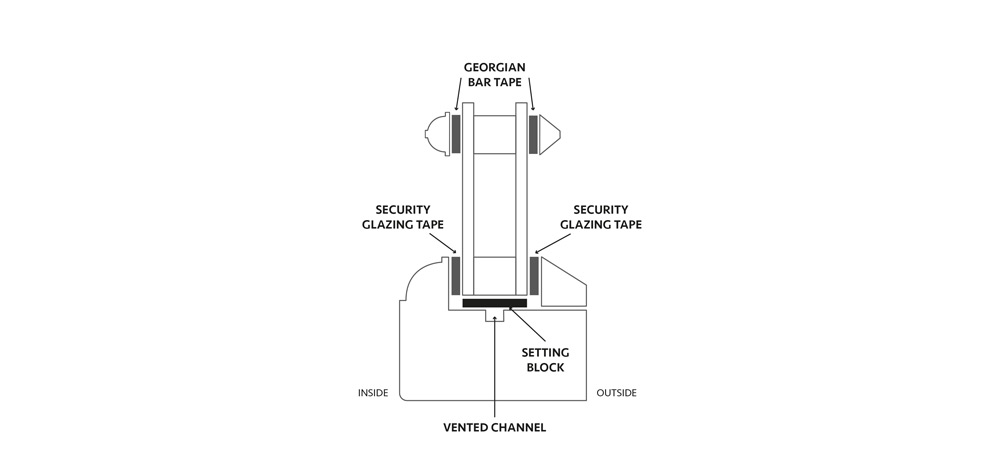

Drained & Vented

FOR FACTORY FITTING & SITE FITTING

This system of glazing can be achieved using many different combinations of products. The ‘Drained & Vented’ method which is now more widely used, will allow moisture within the rebate to escape via a vented sash or the glazing bead. This system can be applied either on site or within a factory environment as you are allowing the free movement of moisture. SDH tapes have been tested by BSI and BBA for security (See prices below) Qwood is also a good option for this system as it creates a very clean and simple pinless glazing solution.

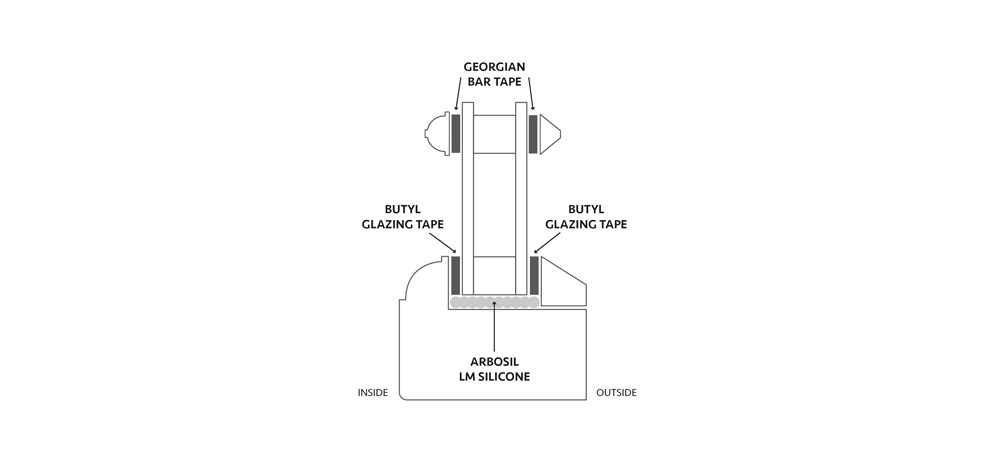

This system of glazing is where you encase the glazed unit with butyl Arboseal GZ tape and Arbosil LM Silicone. This method is a traditional system of not allowing any moisture to penetrate the tapes and affect the glass unit, therefore preventing the unit from failing. This system can only be applied within a factory controlled situation and NOT fitted on site. This is due to the requirement of being able to control the relative air moisture, so that you do not lock moisture within the rebate.