FREE UK DELIVERY

On orders over £60 (Trade £95)

FREE UK DELIVERY

On orders over £60 (Trade £95)

Technical Knowledge

Experienced & Dedicated Staff

Trade Discounts

Register or login for trade prices

16 June 2023

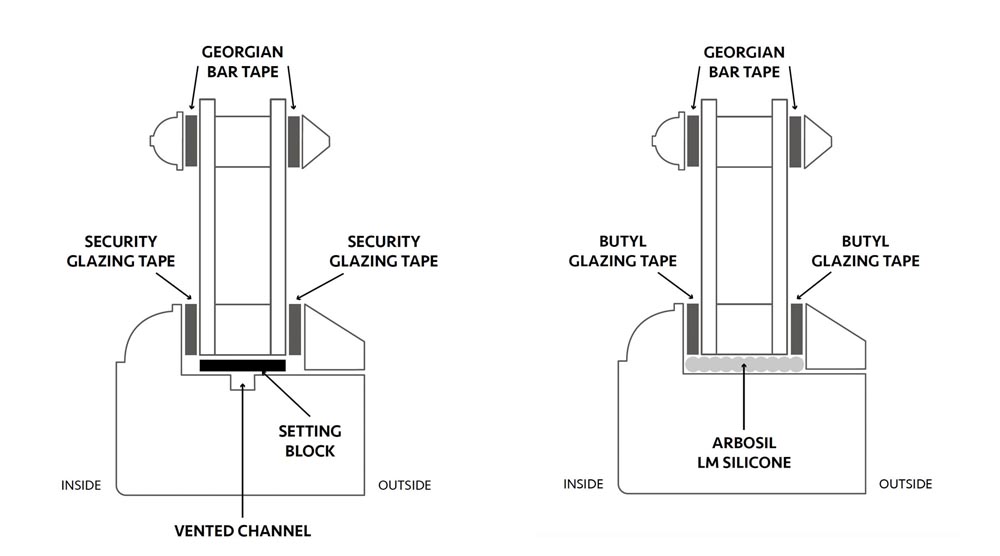

Traditionally, timber windows have been externally glazed. The major reason for glazing doors or windows from the outside is there is a rebate that is part of the sash. This prevents water entering the glazing rebate into the inside of the window (Please find illustrations below) and damaging the interior decoration and fabric of the building.

Indeed, the above sounds like a great reason to glaze the windows from the outside, especially when windows were fully bedded using putty and butyl tapes, along with glazing silicone, to secure the glass within the glazing rebate and bead (shown above). This type of glazing is known as fully bedded and was the popular application until recently. However, the evolution of PVC glazing tapes has provided alternative methods for glazing timber windows, moving away from the expensive and messy option of butyl tapes.

Security glazing tapes not only act as moisture and water repellents but also serve as a security measure, preventing intruders from pulling the glass away from the glazing rebate after removing the glazing beads. Another benefit of using high-performance PVC glazing tape is that your windows can be drained and vented, unlike the fully bedded system. While foam tape resists moisture or water entering the glazing cavity, there may be rare occasions when it fails. By creating a channel as part of the machining process (see image A below of glazing rebate with drained and vented channel), any moisture or water ingress can naturally drain into the extra cavity and escape through the bottom of the sash where the holes would pop through. (see image B below)

IMAGE A

Image B

Drained and vented glazing offers the advantage of on-site glazing, unlike the fully bedded system, which can only be done under factory conditions due to the inability to control the relative moisture content on-site. This is not just a preference but a regulation that should be adhered to by all domestic windows and doors installed.

Today, the majority of joineries manufacture windows using the drained and vented glazing system with various profiles and designs, primarily with an external bead. Q Wood beading profiles have greatly facilitated this trend with their various bead profiles that can be pinned or, even better, a non-pinned clip system that eliminates problems associated with pinning beads (see drawing below).

Image of an externally glazed window with a Pinned Bead. Over time the pins can rust causing damage.

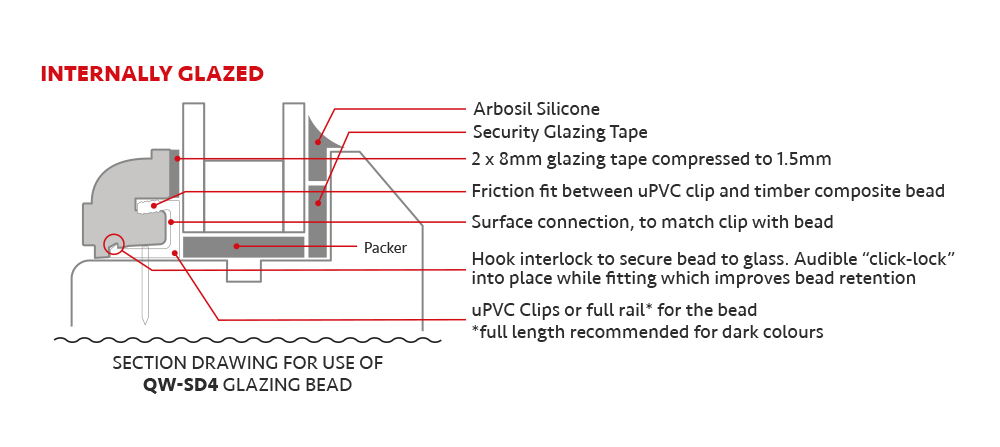

The transition to internally bead timber windows has been approached cautiously due to concerns about tape failures and moisture seeping into the building's interior. However, most PVC window systems now apply internal glazing as standard, utilizing drain-through sashes and incorporating a drained and vented channel to trap any water that manages to pass the tapes. This water will be quickly expelled through the top and bottom drainage holes, ensuring that no water enters the inside of the window.

The benefits of internally glazing a window are many, starting with the fact that your beads are now on the inside of the building, protected from rain, snow, and sun, which can affect the size and appearance of your window from the outside. The controlled and consistent humidity and environment inside a building ensure that your bead, and indeed your entire window, will last longer, perform better, and maintain its appearance. This system is a major benefit for joiners and homeowners.

Additionally, the ability to glaze windows from the inside eliminates the need for expensive and time-consuming scaffolding or powered access. In cities like London and the surrounding areas, where accessing buildings from the road is costly and challenging, this glazing system not only saves time but also crucially reduces expenses, keeping both homeowners and fitters satisfied.

SDH has invested in tooling to introduce a new range of internally glazed Ovolo Beads (QW-SD2 & QW-SD4), matching Astragal Bars, and a unique clip system in Q Wood. This investment will assist joiners and homeowners in achieving better-performing windows that outlast externally beaded windows. Furthermore, there will be significantly fewer remedial call-outs due to bead shrinkage and pin issues.

This glazing process is currently being employed by numerous renowned joineries in the UK, capitalizing on the evident advantages outlined in this report. By implementing this process and utilizing Q Wood beading, your company can position itself at the forefront of the industry, attracting a larger customer base. Additionally, by manufacturing a product that boasts enhanced longevity, your company can generate increased profits.